Harnessing developing technology to produce high-precision microparts for any industry

Welas Oy Ltd provides exceptionally fast production and delivery to its customers. According to Managing Director Livio De Cet, this makes the company stand out in the laser machining industry.

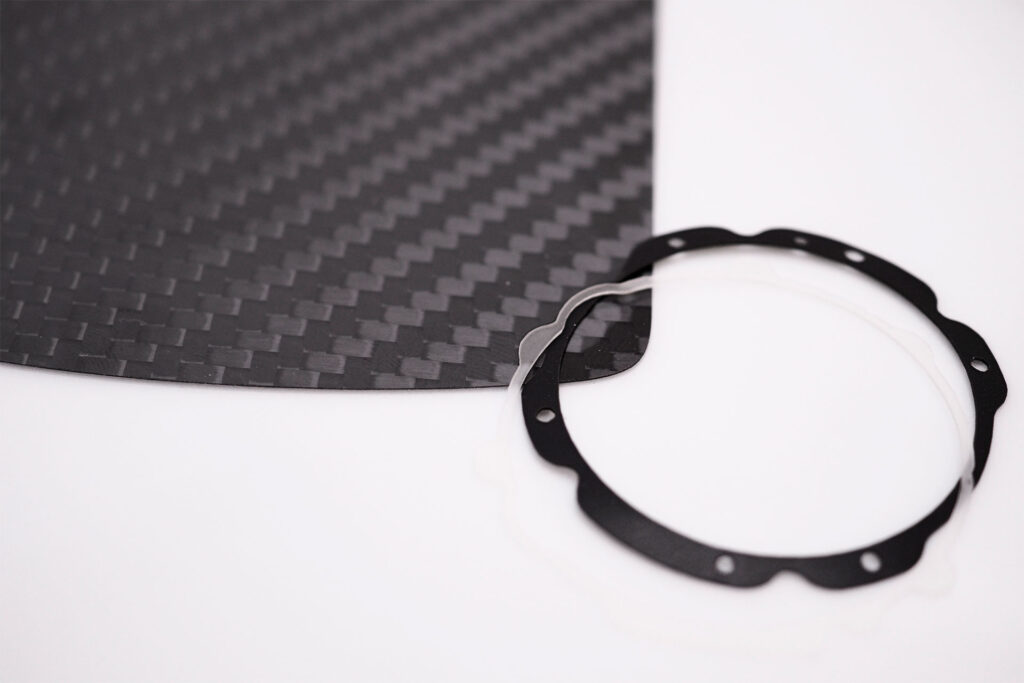

Welas is well-known for its laser technique and custom-designed components, particularly in producing and delivering small or thin parts with high precision. From the first contact with the customer to the moment of delivery, the Welas’ team is committed to premium collaboration. This ensures fast production and delivery for the customer, regardless of the volume of the order.

Speedy delivery and communication make all the difference – building long-lasting cooperation

Not only does Welas succeed in being an efficient and swift supplier, it is also recognized for its steadfast commitment to quality standards and communication. De Cet says: “Satisfied customers are in our DNA”, highlighting the service ethos of the company. The soul of the business is to find the most suitable solutions for each customer by listening to their needs. For that to happen Welas relies on its people. Their experience and know-how are often rewarded by returning customers.

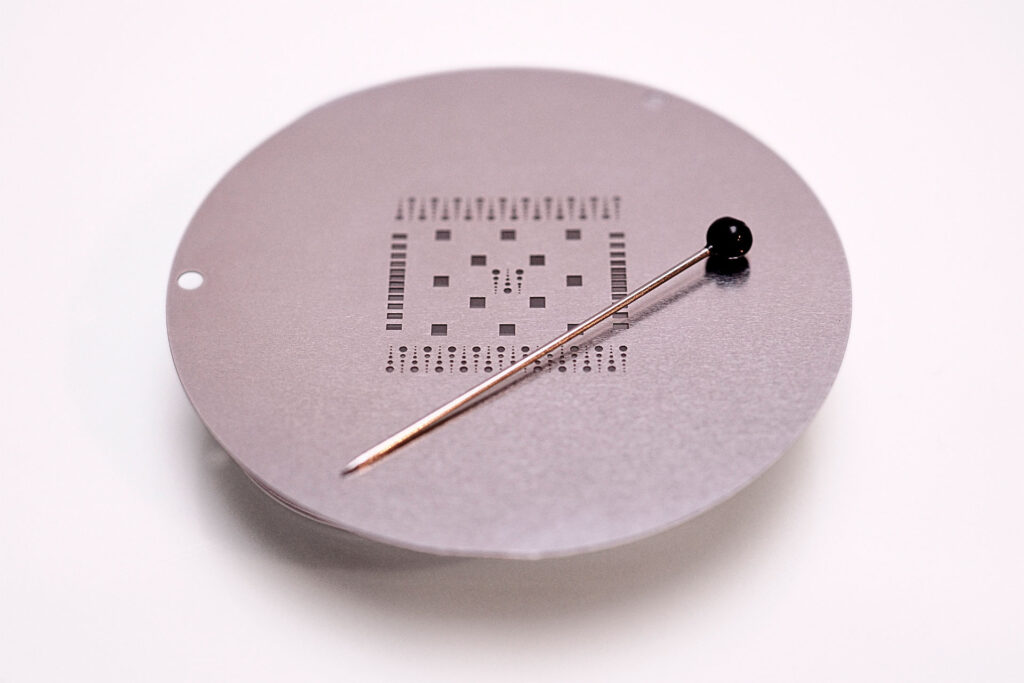

Within the processing industry using CNC machining, particularly micropart suppliers may be difficult to find, as the technologies needed are very new. Welas, however, has the expertise and the insight to tailor innovative solutions for different needs and materials.

According to De Cet, Welas is all about specialists producing and delivering the best possible products for their customers. Cooperation with clients is based on a shared appreciation of new techniques and high quality.

State-of-the-art technology drives outstanding results

The technology that Welas uses is the newest and most effective in the industry. They are laser-lovers, as De Cet puts it, but also invested in looking beyond what they have already done in micro-dimensional components.

An example of this is the Cold Ablation technique. It does not cut through the materials, like other laser machining methods, but rather peels the material layer by layer. This mechanical removal of the material uses ultra-short pulses to guarantee outstanding properties for the final product.

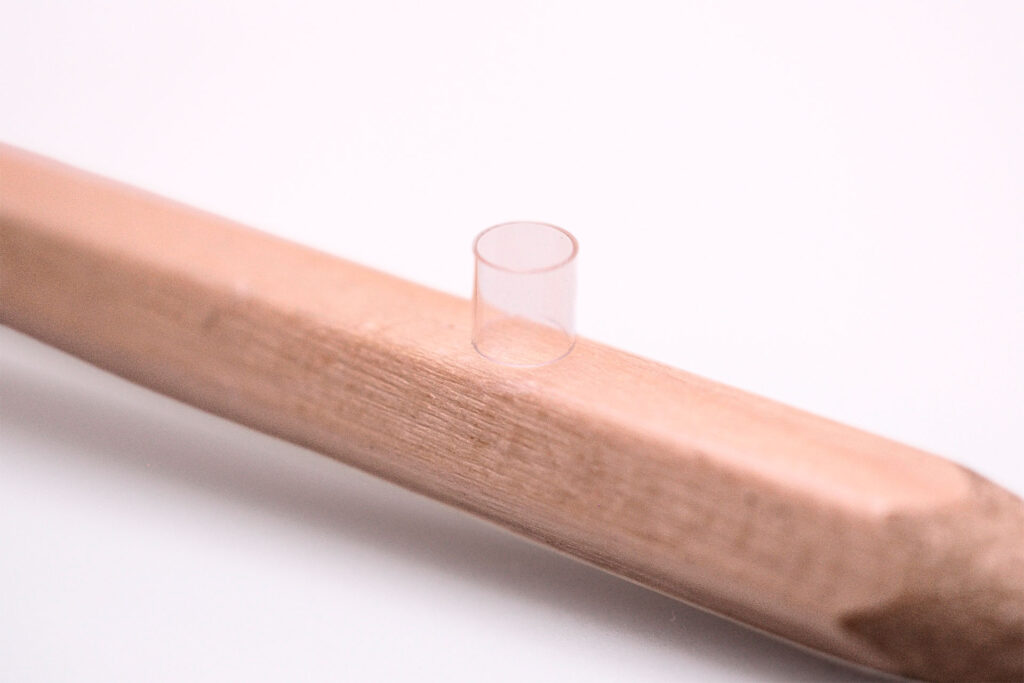

Cold Ablation is a visionary new technique that enables the manufacturing of a range of extremely high-precision products. It permits the production of components with dimensions measurable in less than a millimeter and with very high tolerance levels.

Additionally, this method is very gentle for the material and does not have as much of a heat effect as other techniques. This enables Welas to deliver components from varied materials like polymers, carbon fibers, glasses, industrial stones and ceramics as well as the usual materials like stainless steel, copper, brass, gold and silver. This brings Welas to an advantage compared to other companies in the field.

Welas’ key promise to the customer is to meet ultra-specific needs with excellence

In the near future, Welas aims to delve even further into groundbreaking technologies and methods. De Cet paints the picture of the company’s future by explaining the potential of ongoing development: “We are currently working mostly with millisecond lasers, in terms of pulse length, but there are picosecond and femtosecond lasers overtake.” With these advanced technologies, parts quality is remarkable.

Welas has both the ability and the experience to create innovative manufacturing solutions, prototypes, and experimental products for practically any industry. It already has an established role in supplying parts and assemblies to the medtech, energy, and defence industries, as well as aerospace among others. Potential future partnerships could include also new industries such as fashion that have a demand for effortless and speedy delivery of custom-designed high-precision components.

Tailoring high-precision microparts for varied industries with new technologies is what makes Welas stand out. “If you have trouble finding a supplier for something that is not there yet, particularly microparts, we can assist you. We’ve already done it in another context”, concludes De Cet.